When are corrugated cable pipes really useful and in what cases can you do without them when installing electrical wiring in a country house? Let’s figure out.

When is corrugation pipe useful?

Inside the house:

- To restore order in hidden electrical wiring, for example, wiring power lines, different-sized wires, and low-voltage lines (Internet, fire, and security alarm system cables, intercom, video surveillance) through different channels.

- For the sake of aesthetics: open corrugated wiring looks more reliable, better built, and more aesthetically pleasing than just cables laid along the walls and ceiling.

- Just in case: to be able to replace small straight sections of the power cable without chiseling the walls. For example, when doing a small home automation repair, you can try to carefully pull out a flexible alarm or communication cable, connecting it securely to a new one. But it’s unlikely to be possible to pull a long power cable through even with one bend.

Outside:

- Underground. The protective sheath contains underground cables that supply landscape lighting, drives for automatic gates, well pumps, and sewage treatment plants with forced aeration. This enhances protection against moisture and reduces the likelihood of mechanical damage.

- Above the ground. Corrugations are also used for additional protection from moisture and aging in the sun of cable assemblies during open-air wiring (on hangers). For example, from a house to a bathhouse, a utility room, a street lamp in a gazebo, etc. Protection is especially useful for delicate cables of low-current systems (video surveillance, Internet, communications, intercom, security, and fire alarms).

- For aesthetics and additional protection of cables during open installation of power lines on different bases: walls, beams, plinths, etc.

Which corrugation pipe to take

White or gray corrugated polyvinyl chloride (PVC) pipes do not like long-term contact with ground moisture, and under the influence of daylight, they age and begin to crumble. There is no fire resistance either: although PVC does not burn at high temperatures, it does melt. The ideal place for PVC corrugation is in the thickness of monolithic concrete, floor screed, under a layer of plaster in the grooves of brick and aerated concrete walls.

Black and orange corrugated pipes made of low-density polyethylene (HDPE) are more durable and resistant to solar ultraviolet radiation. Therefore, they can be used both for underground installation and for outdoor wiring. But in no case indoors – such pipes burn well and can cause fire to spread throughout rooms and floors

Blue polypropylene (PPR) corrugated pipes are similar in properties to HDPE, that is, they are resistant to ultraviolet radiation and mechanical loads. The main difference is fire resistance: in the event of a fire, they will reluctantly melt but will refuse to burn themselves. These can be used underground, outdoors, and indoors.

Also, to protect cables and wires, galvanized metal hose is used, which is made from steel tape. This can be produced in a protective sealed shell. The main area of application is additional mechanical protection of cables outdoors and in difficult industrial conditions. It can also be used for temporary cable protection, for example when providing power to a construction site. In the ground with constant contact with moisture, such “armor” does not last long.

What corrugation pipe does not guarantee protection from?

You should not expect that such wire protection will save you from:

- thermal damage with melting of the cable insulation, and even more so from fire: the corrugations will burn out faster than the insulation

- damage and destruction of cable sheaths caused by prolonged contact with moisture or constant exposure to a humid environment

- serious mechanical impacts, for example from accidental damage to a hidden cable with a drill

It is important to remember that corrugation is only additional protection. But there are cases when “packing” cables into corrugations is extra work that cannot be explained by electrical and fire safety requirements.

Is corrugation pipe needed for wires in a stone house?

If the walls and other structures are made of non-combustible materials, and the cables have a protective sheath, then no.

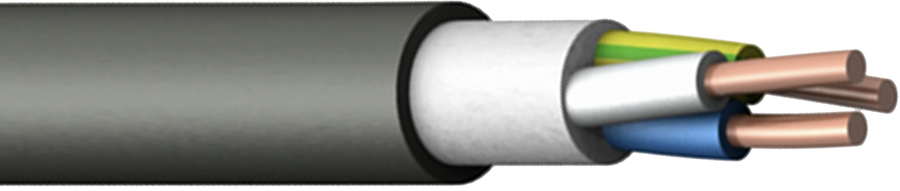

As a rule, cables of the VVGng LS and NYM brands are used in home installations. The first has double insulation (protective shell) made of flame-retardant PVC plastic with reduced smoke and gas emissions, the second has triple insulation. It is not necessary to put them in the corrugation when installing hidden wiring.

There are situations when corrugation only gets in the way: for example, when laying cable routes in load-bearing reinforced concrete walls that cannot be chipped (that is, making grooves for laying wires). A cable with a diameter of 10–12 mm without additional “packaging” will require a much smaller layer of plaster to “cover” than the same one but in a tube with an outer diameter of 20 mm.

Is it possible to use corrugation pipe in a wooden

or frame house?

Everything is more complicated here: nowhere in the requirements is it written in plain text what is allowed and what is not allowed in a wooden house. At the same time, the standards make distinctions for hidden wiring in combustible and non-combustible environments.

Open wiring of wires and cables in a protective sheath can be done.

Hidden wiring in wood and other fire-hazardous structures must be additionally protected with a non-flammable sheath.

Plastic corrugations will not save you from a fire, although they will not cause any harm. And in any case, you will have to bear additional costs. You will have to make sure that the structures are fireproof: thermal insulation is based on non-flammable basalt wool, fire-resistant plasterboard, plaster, etc.

Let’s sum it up

There is no practical sense in using corrugation pipes when installing VVGng and NYM cables. Essentially, this is a spare layer of insulation that does not provide complete protection. It also does not pose a danger – except for the customer’s not always-justified confidence that everything was done professionally and “as it should.”

Such confidence is a sure chance to lose sight of other, no less important fire safety measures, such as calculating the load on the electrical network, using certified “automatic circuit breakers” and high-quality cables without “twists” in hidden cavities, using non-combustible materials, as well as treating combustible structures with fire retardants and antiseptics.