Horizontal waterproofing of the foundation involves treating the surfaces of the strip or slab base with protective compounds. This procedure helps to increase the protection of the structure from the spread of liquid resulting from contact with groundwater, meltwater, or atmospheric moisture contained in the air. The procedure is performed using various materials, the main feature of which is the creation of a barrier layer when processing concrete.

WHY IS HORIZONTAL WATERPROOFING PERFORMED?

The main purpose of waterproofing horizontal surfaces is to prevent the spread of capillary moisture, which can accumulate in concrete and subsequently be transferred to the walls. If you do not follow this procedure, you may encounter the following disadvantages and problems in the future:

- reduction in the strength of concrete – a monolithic material, despite its apparent strength, can be significantly damaged by excess water content or prolonged contact with it. Thus, the liquid washes out mineral substances from the cement stone, which are the binding components. As a result, shedding appears, internal cavities increase, which leads to a decrease in strength;

- formation of cracks – in winter, moisture accumulating inside poses a particular danger. When water particles freeze, they turn into ice, significantly increasing in volume. In practice, this leads to the formation of chips on the monolith, and in the most severe cases, to the appearance of cracks;

- corrosion of reinforcement – metal reinforcement suffers most from capillary moisture. Over time, it becomes covered with rust, which leads to a significant decrease in strength and elasticity. As a result, cracks and subsidence of the slab or base tape may appear;

- the appearance of mold, wetness of the rows of masonry, and finishing in contact with the base – the liquid flows upward through internal channels and voids and is transferred to the rows of brickwork or wooden crowns of the walls. The result of this impact is a decrease in their strength, the appearance of serious damage, mold, and mildew.

Thus, horizontal waterproofing plays an important role in organizing the protection of load-bearing parts and walls of a building. By performing this procedure, you can significantly extend the service life of the object.

WHEN WORK NEEDS TO BE DONE

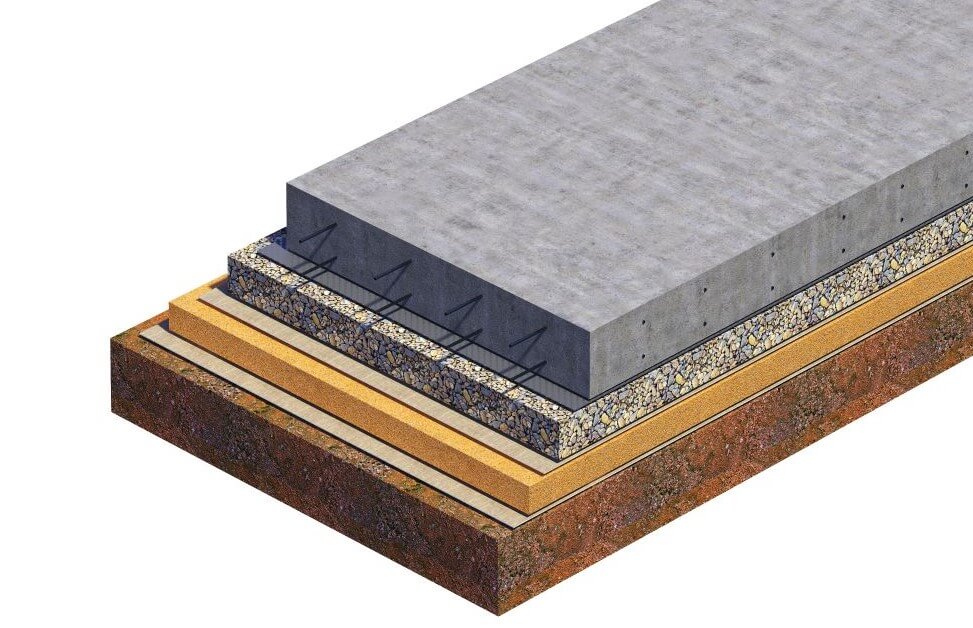

To obtain an effective result, work must be carried out at the construction stage by the foundation pouring technology. Horizontal waterproofing can be applied in two ways:

- on the lower part of the base – rolled materials are laid on a previously prepared bed of sand and gravel, which has undergone the leveling and compaction procedure. Also, when installing strip foundations, it is recommended to pour a screed of lean concrete around the perimeter to increase the load-bearing properties of the material;

- on the upper part of the foundation – after pouring and hardening of concrete, the upper part is covered with rolled, coating, or membrane materials in the area where external walls and internal partitions are laid. In the case of a slab foundation, it is recommended to treat the entire area so as not to encounter dampness under the floors in the future.

In practice, it is recommended to perform both procedures to obtain truly high-quality and effective protection. If the work was not carried out on time and several years after the operation of the building you are faced with the problems described above, it is recommended to carry out the procedure of injection of concrete and brickwork. During this work, internal cavities are filled with special solutions with the effect of crystallization and filling of voids.

ROLL MATERIALS

This category of waterproofing products includes bitumen roll waterproofing, laid on the surface and fixed to it using special adhesives or by fusing. For production, modified bitumen is used, which is impregnated with pieces of fiberglass. The result is a material that is resistant to temperature and climatic changes with a durable and tear-resistant fiber structure. Roll materials are universal in their performance properties. They can be used both for the substrate when organizing the lower protective and separating layers before pouring concrete, and for the upper separating layer before carrying out masonry work. The disadvantage is the relatively labor-intensive installation process, especially when working with built-up waterproofing.

PENETRATING COATINGS

Penetrating coatings are made based on cement mixtures, which may also contain various mineral fillers and polymer-type additives that increase the elasticity and adhesive properties of the material. The compositions can be one component (mixed with water) or, two-component (mixed with the second liquid component included in the kit). The advantages of such compositions include the following:

- penetrating effect, ensuring the filling of surface pores and blocking the spread of moisture through them;

- compatibility with any mineral surfaces, grades of concrete of different strengths;

- ease of use – application is carried out using a spatula;

- good adhesive properties, ensuring reliable connection to the surface;

- good load-bearing characteristics that allow waterproofing to withstand the impact of the mass of masonry on the surface.

Compositions of this type are becoming widespread and are increasingly used in construction due to their positive properties and characteristics.

LIQUID MEMBRANES

For the manufacture of waterproofing membranes, modified bitumen, synthetic rubber, silicone, and other additives are used. The composition is supplied completely ready for use and does not require preheating or other processing steps. Apply directly from the container using a brush or roller. It has the following important advantages when used:

- penetrates the pores, blocking the spread of moisture and firmly connecting to the surface, exfoliation of the material during further use is excluded;

- easy to apply with a brush or roller to a clean and dry base;

- is resistant to mechanical and climatic external influences;

- applied without seams, forming a monolithic coating;

- has a long service life.

Membrane coatings provide high-quality and effective results and are suitable for treating large areas, in particular the entire surface of slab foundations.