Imagine that your faucet in the bathroom or kitchen is leaking, and you are not able to turn off the water. The cold water supply ball valve, which is placed at the beginning of your distribution from the house riser, does not close completely. Common situation? Surely many who found themselves in it, in a panic, called the management company, called bulletin boards, or simply looked through their friends for a plumber who could cope with this task.

This phenomenon is not so rare. And this is even though modern ball valves are practically the crown of plumbing thought. Their use is practically standardized. No home or apartment wiring is complete without ball valves for cold and hot water. What is the matter then and why do such emergencies still happen? Let’s figure it out together.

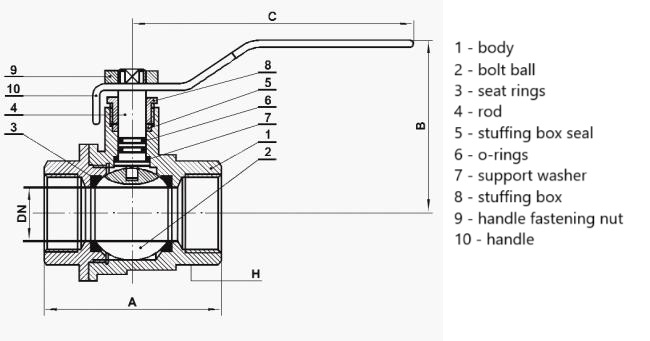

Ball valve device

The base of the tap is a polished brass ball with a through hole and a shaped recess for the stem. This type of crane can rotate within 90 degrees. The movement of the ball inside the body is softened by fluoroplastic or Teflon gaskets called seats. The rod is sealed by a pressure bushing with an external thread and a nut at the end. The valve body can be solid or divided into two parts connected by threads. Most often it is made from brass, choosing a thickness for the walls with a margin of safety. But there are also cheap models. Their body is made of silumin or lightweight brass, on which the manufacturer simply saved money.

Method of resuscitation of a ball valve

To be fair, we warn you that this option does not provide a 100% guarantee of restoring the operation of the ball valve. However, this is the most correct path to follow before replacing it.

To begin with, you should try to design a faucet valve by hand. If the result is zero, do not force the faucet and use pliers or adjustable wrenches for this, turning the butterfly handle to the bend with force. This can only make things worse, because you may not know what the faucet itself is made of – high-quality brass or cheap silumin. The latter, by the way, breaks down once or twice, as soon as you touch it with some kind of lever, and very quickly turns the bathroom and entire apartments into a pool with cold water.

So, unscrew the euro nut and remove the butterfly handle. Below it is the top of the valve stem. Some taps have a pressure sleeve for a hexagon, which presses on the seal inside the tap. If the rod turns with difficulty, this bushing must be slightly loosened.

Next, using an adjustable wrench, carefully and slowly develop the rod, turning it from side to side. In this case, you should not make sudden movements, otherwise, you risk breaking the rod or ball, which will lead to a complete breakdown and jamming of the faucet valve.

During this procedure, light streaks of water may form at the top of the faucet. This is a normal phenomenon considering that the clamping sleeve is loose.

To check the serviceability of the faucet, you need to place the butterfly in its seat and try to turn the valve with it. Based on the risks to the body, you will immediately see the result. If you can turn the valve all the way, tighten the clamping sleeve and put the butterfly in place.

Practical advice

To avoid getting into a situation where the faucet is coked by lime or metal deposits, you need to turn it on 1-2 times a month, turning the valve to the maximum level.

Use only high-quality locking hardware from trusted manufacturers. Do not skimp on items such as ball valves, because their breakdown can be very expensive.