What is FUM tape and what should be taken into account when choosing it. Simple instructions for winding sealant on large and small threads.

A threaded connection will not be airtight without a seal. Linen tow was traditionally used as a sealant, which was additionally impregnated with red lead, paint, or sealing paste. The connection turns out to be airtight, but ugly, and it takes a long time to tinker with it. Modern seals, such as FUM tape, also give good results, and they are easier and faster to use. Let’s figure out how to easily wind FUM tape onto a thread.

FUM tape: what is it?

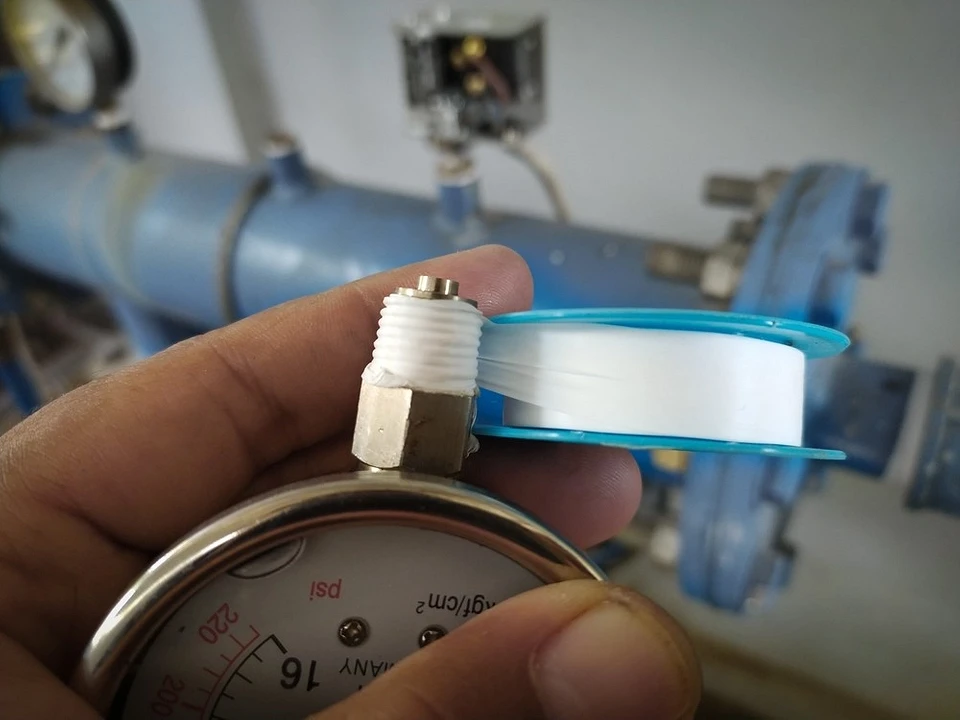

This is a modern film-type sealant, it is used for sealing flange, threaded, and nipple connections. The name contains an abbreviation that stands for fluoroplastic sealing material. It is made from fluoroplastic-4. Raw plastic fibers are rolled out, formed into a tape, and then dried in a vacuum chamber. The finished seal is heat-resistant, resistant to a wide variety of adverse influences, completely safe, and lasts a long time. In addition, it has antifriction, that is, it reduces friction, so that the thread does not break off when tightening.

What to consider when choosing a winder

Externally, all products look approximately the same. This is a reel with a white tape wound on it. However, you shouldn’t take the first one you come across; you need to select a sealant for the thread. They are wide and narrow. The former has a width from 12 to 19 mm, sometimes more. Materials up to 12 mm wide are considered narrow.

The thickness distinguishes between thick and thin seals. They can be distinguished even by their appearance, but it is better to read the markings of the coil. A material with a thickness of 0.12 to 0.75 mm is considered thin. When unfolded, it literally “glows” and you can see objects through it. But it’s not transparent, like, for example, adhesive tape, it’s just very thin. Thick type – quite dense. Its thickness is from 0.1 to 0.2 mm. Narrow and thin types are recommended to choose small threads for winding, for example, 1/4 inch, or similar. For large ones – 1 inch and the like – thick, wide material is suitable.

It can be difficult for a novice craftsman to choose a sealing material. Above we have provided average data that will help you do this. However, there are a lot of tapes of the same density and width on the market. Experienced professionals advise you to start by buying three or four products from different manufacturers, and testing them on different connections to settle on “your” version.

Simple instructions on how to wind FUM tape

The winding process is not complicated, but you need to do it right. After all, the sealing of the connection depends on how well the seal is wound. The winding technique depends on the size of the thread. Let’s look at how to use FUM tape in different cases.

For large threads

To seal such a connection, a wide, high-density model is best suited. If necessary, you can take a thin or narrow one, but then you will need to make more turns. No additional tools are needed. You need to wind it like this.

- Prepare the threaded connection. It must be clean and dry. If the part is not new, thoroughly clean it of any remnants of the old seal, rinse, and dry.

- Take the reel, unscrew the edge of the ribbon, place it on the thread, and press to secure it.

- Pull the material with a little force and begin to wind it with tension. The seal should “fall” into the threaded threads. The first few rows of winding should be visible.

- Wrap five or six rows of dense material, or 13-14 thin ones, trim the edge, and press it to the part. Important. The number of winding rows is determined during the work process; there are no exact standards here.

- Assemble the threaded connection.

Important point. The seal is wound only under tension. Otherwise, it will slip off the teeth and the connection will not be tight.

For small

Winding the seal onto parts with fine threads is done differently. For work, take only a thin narrow ribbon, a wide and dense one will not work. The instructions on how to wind FUM tape are as follows.

- Prepare the part. If necessary, clean the threaded teeth, rinse and dry.

- Take the reel, and grab the edge of the ribbon. Pull it forcefully so that the fabric stretches into a thread.

- Press the thread against the edge of the thread to obtain a fairly tight fixation.

- Start winding the seal. During the winding process, place the thread sequentially in each curl.

- Wind the tape so that it overlaps the entire width of the threaded connection. On average, this is about 20 revolutions. Cut and secure the edge.

- Assemble the part and tighten it.

Basic mistakes when winding

The winding technique is very simple, however, craftsmen, especially those with little experience, make mistakes. Let’s look at the most common ones.

Wrong winding direction

You only need to wind the seal along the thread. You cannot change direction. If the ribbon is wound against the movement, in the process of tightening the part, its teeth will move. It turns out that the turns will remain without a seal. Water will flow through these areas. Important point. If a turn is accidentally missed during the winding process, you must carefully unwind the ribbon to the missing section and repeat the winding. Otherwise, the connection will be leaky. Do not bend the ribbon while winding. The material is wound unevenly, which impairs sealing.

Reuse

Experienced craftsmen advise remembering that it is strictly forbidden to reuse the tape if it has already been wound on the thread. Even though the material is elastic, when winding it will tear on the sharp teeth. The peculiarity of the FUM tape is that it breaks better along rather than across. Therefore, damage may not be noticeable. But after re-winding, when tightening the part, the material will tear. This will worsen the sealing, in addition, fragments of the tape may get inside the line. They will clog the pipe and reduce the opening for the passage of liquid, which is extremely undesirable.

Insufficient number of turns

There is no general rule determining the number of turns of a FUM tape. The number of turns is determined experimentally. It must be understood that if there is an insufficient amount of winding, the connection will be leaky. If the number of revolutions is too high, the thread will be difficult to tighten. Excessive tightening force will cause the seal to slip and become depressurized.

Poor preparation of the part

FUM tape is wound only on a thoroughly cleaned part. Particles of dirt, even very small ones, will prevent the material from sticking to the base. When tightened, it will move. In addition, under a poorly laid seal, voids remain, which will then cause leaks. There is an opinion that winding a large amount of FUM tape helps restore the “eaten” thread. Allegedly, the material fills the voids and the tightness is restored. This is a serious misconception. FUM tape is very plastic; under pressure, it will shrink and will not prevent the flow of liquid. Therefore, you should not hope for the restoration of the thread.