We talk about the features of choosing heating pipes for a home and their varieties. We give useful advice on choosing a product.

The heating system is responsible for the warmth in the house. All its elements must work accurately and smoothly, with minimal heat loss. Only then will the house be warm. Not only the boiler and radiator but also other elements must be selected correctly. Let’s look at which pipes are best for heating in a private house.

What to look for when choosing

Assembling the heating circuit consists of installing a boiler and radiators; these products do not require any modifications. They are mounted in certain places and connected to a common circuit using a pipeline through which the coolant will circulate. Pipes have important technological requirements.

- Completely sealed.

- Sufficient strength.

- Lightweight.

Elements with these properties can transport coolant normally. In addition, there are several consumer characteristics that also need to be taken into account. They do not affect the operation of the heating circuit but make it more comfortable for the owner. Let’s list these characteristics.

- Silence. It is good if the liquid moves silently or with minimal noise.

- Maintainability. It is desirable to be able to quickly and inexpensively repair an element that has become unusable.

- Difficult to install. It is best if you can install it yourself without using special tools.

- Appearance.

- Installation and maintenance price. It is advisable that it not be too high.

What is important to know when choosing heating pipes for a home

The main difference between a centralized heating system and an autonomous one, which is used in private homes, is the working pressure of the coolant fluid. For high-rise buildings, a value of 5-6 atm is considered normal; during the period of flushing and startup, the figure increases to 16 atm and even higher. This is due to the design features of the system. For autonomous heating such values are not needed. The circuit is much shorter; 1.5-2 atmospheres is enough for fluid movement; with pressure testing, the figures are higher. This must be taken into account when choosing and focusing on low or average operating pressure, there is a chance to choose a not the most expensive option.

Types of heating pipes

To assemble the heating circuit, different elements are used. Let us briefly describe the most suitable options for a private home.

Steel

Ferrous metal is used for their manufacture. After assembly, the outline needs to be painted.

Pros

- High strength, and resistance to pressure surges.

- Good thermal conductivity.

- Low thermal expansion, no compensators needed.

- Resistance to mechanical damage.

Minuses

- Difficult installation requires a welding machine. You can do it differently and assemble a steel pipeline using threaded connections, but this is very labor-intensive.

- Considerable weight.

- Electrical conductivity and susceptibility to corrosion.

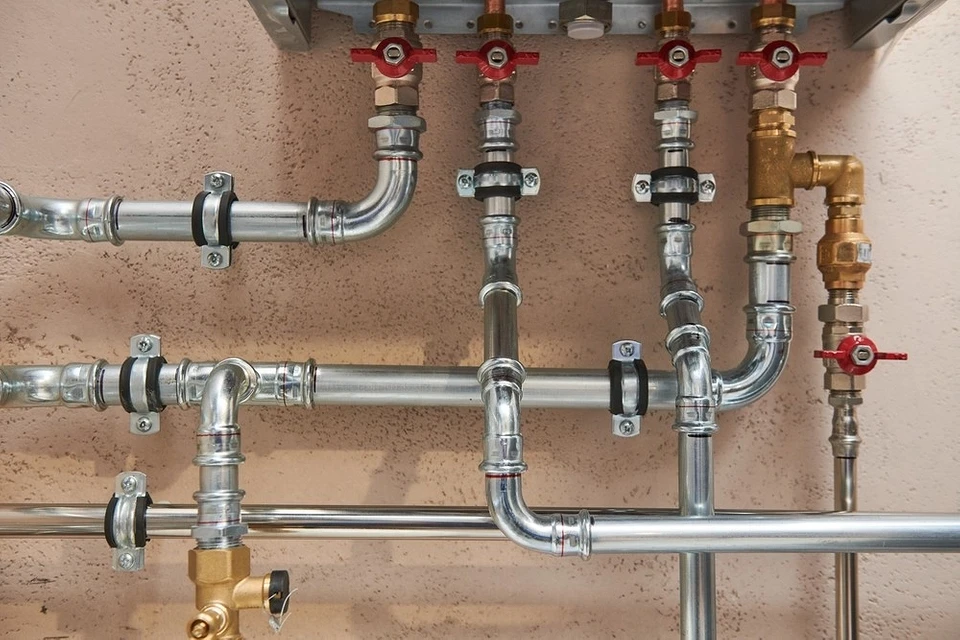

Stainless steel

The elements are made from stainless alloy steel and can be corrugated or smooth. They are suitable for heating systems and water-type underfloor heating.

Pros

- Good thermal conductivity.

- Easy installation due to the flexibility of the elements.

- Resists corrosion and scale accumulation.

- Attractive appearance, no painting required.

- Reliability: withstand heavy loads, insensitive to mechanical damage and water hammer.

Minuses

- High price.

Polypropylene

Propylene pipes for heating in a private house are marked PP. Made from fiberglass-reinforced polypropylene. This gives them the ability to withstand pressure up to 25 atm and heat up to 95˚C.

Pros

- Lightweight, which greatly simplifies installation. It is simple and is carried out using a special soldering iron, which you can learn to work with very quickly.

- Durability, long service life of 50 years or more.

- Resistant to negative temperatures. When water inside a pipeline freezes, its walls expand but do not collapse. After defrosting, they return to their original position.

- No noise when transporting liquid.

- Low price.

Minuses

- The linear expansion rate of polypropylene elements is high, so expansion joints are needed during assembly.

- Rigidity. It is almost impossible to bend the element.

- Low maintainability, therefore, in case of an accident, the section “from fitting to fitting” is replaced.

Polyethylene

For the heating system, products made of cross-linked polyethylene are used, which contain additional bonds between polymer molecules. Reinforced with nylon thread, aluminum foil, or Kevlar. Marking: PEX or PEX.

Pros

- Good flexibility and memory effect.

- Withstands temperatures up to 120˚C, sudden changes in pressure.

- Increased wear resistance, lasts more than 50 years.

- Resistant to corrosion and aggressive chemicals. Suitable for hidden installation.

Minuses

- Quite a complex installation using compression fittings and compression couplings.

- Sensitivity to ultraviolet light.

Metal-plastic

A combined option that combines the advantages of plastic and metal. Marked as PP-AL-PP, PEX-AL-PEX, MP, PE-AL-PE.

Pros

- Simplicity and versatility of installation. Detachable, conditionally detachable, and permanent connections are possible.

- Flexibility, which allows you to reduce the number of connections to a minimum.

- Resistant to high temperatures and pressure changes.

- Minimal linear expansion, so expansion joints are not needed.

- Looks good, no painting is required.

Minuses

- The relatively high price of connecting fittings.

- The internal cross-section of the fitting is smaller than that of the pipe. When water freezes in the pipeline, a rupture is inevitable. Therefore, it is recommended to pour antifreeze into the metal-plastic circuit.

Sometimes a home heating system is assembled from copper elements. Copper has very good performance properties. It easily tolerates low and high temperatures, the system does not collapse when water freezes and withstands strong hydraulic shocks. The metal is ductile and does not corrode. When using branded fittings, it lasts for decades. However, copper pipelines are quite rare. There are several reasons. Copper is incompatible with other materials and requires skilled and expensive installation. In addition, the price of copper products is very high.

How to choose the best pipes for heating a private house

You need to choose taking into account several factors. Let’s list them all.

- Technical data of the heating boiler: fuel type and design power in kW.

- Type of heating circuit: single-pipe or two-pipe, open or closed.

- Area of heated premises.

- Speed and type of coolant circulation: forced or natural.

- Maximum temperature at each pipeline section.

- System installation method: open on the wall surface or hidden inside a cavity in the wall surface.

- The complexity of installation and the possibility of doing it yourself.

- Pipe diameter.

The last factor is very important. It determines how efficiently the system will work. You can determine what pipe diameter to use for heating in a private house using special tables or calculated using engineering formulas. The easiest way is to use average values. Specialists most often choose parts with a diameter of 25 mm for the contour and 20 mm for radiator outlets.

After all the points described above have been determined, it remains to select the pipe material. For self-installation, it is better to choose polypropylene. It is inexpensive and has proven itself in operation. For installation, you will need a special soldering iron, which is easy to learn how to use. Another good option is metal-plastic. It is assembled without special tools, but over time the connections may lose their tightness. True, this can be fixed. If you have the opportunity to spend a large sum, it is best to choose copper or stainless steel. If assembled correctly, such a system will last for decades.