We tell you what wire and cable are and compare them with each other. We explain when it is better to choose a wire and when to choose a cable.

Not all home craftsmen know the difference between a cable and a wire. Some people read that there is no difference between them. Nevertheless, it is there, and significant. Let’s understand all the subtleties of terminology, and learn to distinguish between two conductive elements.

What you need to know about the wire

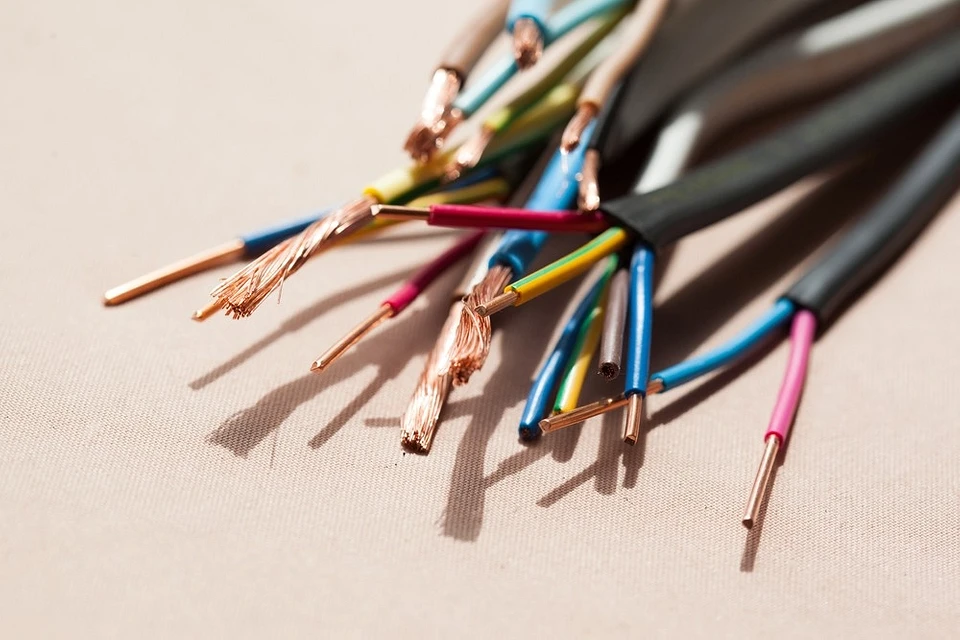

This is the name given to a conductor consisting of one, or in some cases several, cores. It connects sections of the electrical circuit. The core is made of wire, an electric current flows through it. The wire can be aluminum or copper. The cores can be single- or multi-wire. In the latter case, there are several wires twisted into a bundle. The strands that make up the wire are covered with insulating material or left bare.

There are solid and stranded wires. The first is only one conductor, usually copper or aluminum wire. Stranded ones are made from several veins twisted together into a kind of rope. Their advantage is greater flexibility and, accordingly, greater strength. With the same throughput, the cross-sectional area of stranded ones is larger than that of solid ones. Therefore, solid wires are used for high-frequency currents. Due to their strength, stranded ones are in demand during operation with possible mechanical loads.

In any case, the resistance of the wire is minimal, it quickly transmits electric current. At the same time, the throughput is relatively small. Therefore its use is limited. For the most part, it is used inside any electrical distribution devices, as a winding for motors or transformers, etc.

What you need to know about the cable

The conductive element consists of several wires or cores that are necessarily insulated relative to each other. They are additionally covered with a common shell, which can be single or multilayer. Layers can be paper, plastic, metal, and sometimes armored. The number of insulation layers varies, depending on the purpose of the product. The complex structure and multi-layer insulation ensure the long-term operation of the cable.

In addition, in comparison with a wire of the same cross-section, the cable can pass a larger current with less resistance. This is possible because it contains several conductive elements. All of them are reliably insulated, which prevents them from touching; in addition, there is also a multi-layer common shell. Therefore, the cable is used for continuous transmission of electric current in various, including difficult to operate, conditions: in cold climates, underwater, underground, etc.

The main differences between cable and wire

Externally, both conductive elements are similar. To distinguish them, you need to pay attention to several points. Let’s look at each of them.

Marking

Conductive products are marked with letters and numbers. First comes the letter part.

- First letter. Shows what material the core is made of. If it is aluminum, the marking will be A, the copper core is not marked, and there is no letter.

- Second letter. Shows the type of construction. It can be K – control, P – flat, M – assembly, etc.

- Third letter. Characterizes the insulating layer. There can be many options here: K – nylon, P – polyethylene, E – shielded, L – varnished, etc.

- Fourth letter. Shows design features. This can be B – armored with steel tape, T – for laying inside pipes, O – with braid, etc.

Immediately after the letter part, there are numbers.

- First digit. Shows the number of veins; if there is none, then there was only one.

- Second digit. Shows the cross-sectional area of one core in square meters. mm.

- Third digit. Shows the rated voltage that the product can operate with.

If the product contains cores of different diameters, they are all marked in the marking with a plus sign.

Marking helps to accurately identify the type and characteristics of the conductive element. There are a lot of markings, it’s difficult to remember everything. Therefore, to clarify the data, you need to refer to special tables. Here are the letter markings of several common types of conductive products.

Wires

- APV. Aluminum single-core wire with PVC insulation. Suitable for different operating conditions, including wet ones.

- PV1. Analogous to APV, but the core is made of copper.

- PPV. Single-wire conductors with a jumper between them. PVC insulation. Use indoors and outdoors.

- APPV. Analogous to PPV, but with aluminum conductors.

- PBPPg. Flat wire, stranded cores. It bends well, so it is used in areas where wiring must bend.

Cables

- VVG. Power cable with single or multi-wire conductors. There are a large number of its varieties.

- VBBSHv. Power cable with different numbers of cores. There can be from one to five, single- or multi-wire. Insulation and internal filling made of polyvinyl chloride.

- NYM. Analog of VVG, assembled according to European standards. The internal filling between the insulation layers is made of rubber.

Insulation

The presence or absence of insulation may directly indicate the type of conductive product. The absence of insulation or its presence only in the form of an outer sheath, inside which there are bare conductors, indicates a wire. If the section shows several insulated cores that are collected under a common sheath, this is a cable. Moreover, the shell in this case can be single- or multilayer. Insulation can help determine the type of product, but you need to remember that there are wires that have insulated cores inside a common sheath. Therefore, you should not rely only on this sign; it is better to check the labeling.

Voltage

Both electrical products have load limits. The cable has a large overall cross-section and a number of cores; in addition, there are at least two layers of protective insulation. Thanks to this, it can carry more current and cope with a larger load than wire. At the same time, the speed of passage of electric current is also higher. Thus, the voltage indicated on the marking for the cable and wire differs significantly. In the first case, it is hundreds of kilovolts, in the second – units.

Application area

The scope of application of conductive products is different. Wires have a smaller core cross-section and lower insulation strength. They are used inside electrical distribution equipment, in various electrical devices, and as wiring for non-residential and residential premises. The cables have better protection against various damages and higher throughput. They are used in special conditions: in fire-hazardous areas, in mines, in the cold, underwater, and underground. They are installed at industrial enterprises as permanent lines with a significant power load.

Durability

The service life of conductive products varies. The wire is considered the most short-lived of them. It has thin insulation, which makes it vulnerable to mechanical damage. Therefore, experts recommend installing it so that there is easy access for repair or replacement in case of damage. The average service life of a wire is from 5 to 10 years.

The cable has multi-layer insulation protection, designed for operation in difficult conditions. Therefore, a correctly selected and installed product will work for a long time. On average, it can withstand a constant planned load for 25-30 years.

When to use wire, when to use cable

Wire and cable have different applications. This must be taken into account when choosing a product for home use. Usually, when planning construction or repair work, cables are used when laying through walls, they are laid as permanent lines for a wide variety of purposes. Wires are installed inside electrical panels and used for temporary connection of various electrical appliances.

Conclusion: the difference between wire and cable

Let’s summarize and briefly explain in simple words how a wire differs from a cable.

First of all, they have different purposes and significantly different technical characteristics. It is capable of passing large currents through itself and coping with increased load. The wire passes small currents and operates with a relatively low load. It is most often laid indoors or used in overhead power transmission lines.

It is not always possible to distinguish one product from another externally. Wires come with insulated or non-insulated cores inside the sheath, and there are bare varieties. The cable always has insulated cores and an outer single or multilayer sheath.