The wooden finish of the sauna must withstand high temperatures and humidity. Do not burn the human body. What types of wood meet these conditions? Let’s talk.

The walls of the steam room are sheathed with different wood materials, but the most popular of them is lining. This is the name for thin boards, the edges of which have milled grooves and tenons, which, when connected, form a lock. The lining is technologically advanced, easy to install, and lasts for decades.

Choosing a lining

The lining is made from deciduous trees (oak, linden, alder, aspen, ash) and coniferous trees (spruce, cedar, larch, pine). The use of coniferous species in steam rooms is considered undesirable. The high temperature in the sauna (90–110 °C) promotes the release of resin from the wooden paneling, which can cause the effect of sticky walls, and in the worst case, literally burn the skin.

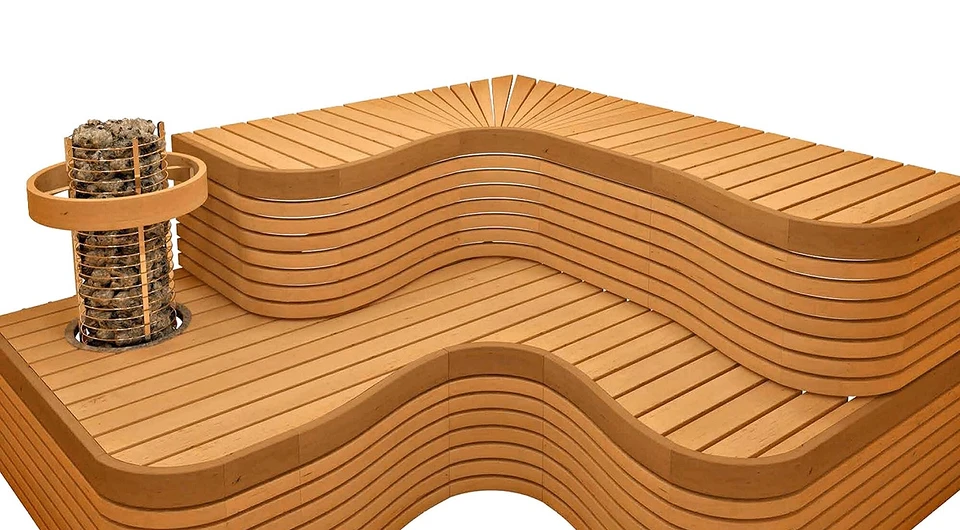

In addition to wall coverings, floorboards, shelves, and backrests are needed to furnish a sauna. The rounded contours of the shelf’s finishing elements make it more comfortable and safe.

At the same time, due to the high content of resinous substances, coniferous wood more actively prevents the growth of mold, fungi, and rot than others. This quality is important for a steam room in a bathhouse, where the temperature is lower than in a sauna (40–60 °C), and the humidity is noticeably higher (55–60%). Therefore, larch lining is appropriate here, which only becomes stronger when exposed to water. By the way, coniferous trees growing in northern latitudes have a noticeably lower resin content.

In a hot steam room, the lower the heat capacity and thermal conductivity of the wood, the more comfortable the contact of the body with the sheathing parts and the less the risk of unpleasant sensations. Abash (African oak) is the leader in these indicators due to its low density (350 kg/m³). The downside of this property is the weak resistance of abasha to mold, fungi, and pests. Lining made from medium-density deciduous trees (about 500 kg/m³) – linden, alder, ash – is a universal material. It is suitable for saunas and bath houses.

- The optimal thickness of the lining is 12–16 mm. Check for grooves on the backside. They promote ventilation and prevent warping.

- Molded wood moisture content is from 12 to 15%. Larger parameters indicate poor drying of the material, which can lead to the deformation of the boards.

- The surface of the lining must be smooth. Then it will not cause unpleasant sensations from contact, and when applying a protective paint coating, it will minimize its consumption.

- You should not use boards with moving or fallen knots, they will ruin the appearance of the cladding.

Read more: How to make proper ventilation in a bathhouse

Rules for caring for wood flooring

Maintaining cleanliness in the bathhouse and sauna is necessary for hygiene and health. Indeed, in warm conditions, in conditions of moderate and especially high humidity, fungi and bacteria actively multiply. If you regularly clean and disinfect the wooden surfaces of the steam room, the risk of the formation of lime deposits and mud stains, mold, and rot will become noticeably less. In addition, these measures will prevent the occurrence of unpleasant odors and together will extend the life of the natural material. The frequency of cleaning depends on the frequency of use of the steam room. And the use of cleaning agents and disinfectants will in any case make it more effective.

Read more: Thermal insulation for sauna – specially designed stone wool