What to do if the chainsaw cuts crookedly? In most cases, this defect can be quickly and easily corrected if you understand the theory a little. Also, so that this lack of saw operation occurs less frequently in the future, let us dwell on the factors leading to such a problem.

How to repair a crooked chainsaw with your own hands

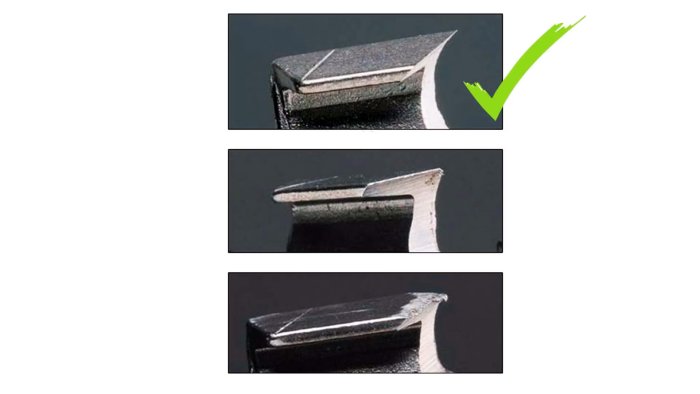

Often this defect is associated with uneven wear of the chain teeth because a tooth has caught a nail or pebble. If this happens, the saw begins to cut worse.

In this case, the sharper teeth of the saw cut the wood easily, and the teeth that catch a nail or stone do not cut off the layer of wood, but roll over.

As a result, the chain begins to put more pressure on one of the ribs, which leads to uneven wear. In addition, uneven wear occurs on the chain shanks moving along the bar groove. Therefore, the chain on the bar has a variable vector of lateral movement, and the longer this continues, the greater the wear on the chain.

The second reason for the rapid wear and tear of the chainsaw bar can be called an incorrectly or incorrectly tensioned chain. According to the instructions, the chain needs to be tensioned so that when you try to lift it on the bar, you can see the bottom of the three shanks. But such a check is subjective, because with different lengths of the chain and different finger strengths, the result is different.

A correctly tensioned chain on a cold chainsaw should not sag or turn without effort. But there are also some peculiarities: on a saw that has been running a little, the chain heats up first, and it always sags slightly.

In this case, some operators rush to tighten the chain. What could this lead to? Let’s say the saw is turned off, which means the chain cools down and becomes overtightened. And if you continue to saw after this, then after the chain, with a certain time lag, the chain will heat up and lengthen. Again the chain will be overtightened.

An overtightened chainsaw chain increases the load on the bearings, sprocket, and bar, and at the same time, it stretches, not only overtightened sharp but also a dull chain, which together significantly accelerates the wear of the bar and chain.

It is clear that if you put a new chain on an already slightly worn tire, nothing will change much. The chainsaw will still cut crookedly, which, however, in many cases can be corrected.

The chain should be sharpened on a stationary machine, and for the first time, it is enough to turn the tire over. If it has been flipped before and the tire has uneven wear on both sides, it needs to be realigned. To do this you will need a square, a vice, a grinder, and a new grinding wheel.

A test cut shows that the saw moves to the side.

Therefore, we remove and check the tire. We put it on a level table, attach a square, and make sure that the wear of the tire is uneven, which can vary in size.

We fix the grinder with the cleaning disk in a vice, raise the surface of the table using a blank and a piece of board to the level of the disk and fix it with clamps. Use a square to set the exact angle of the disc and fix the grinder in a vice. Next, we grind the tire on both sides and eliminate wear. We check the accuracy of the operation with a square.

Make sure that the chain shanks are completely hidden in the groove of the bar. If the groove becomes shallow after grooving, replace the tire with a new one. We assemble the chainsaw and see how it cuts now. It can be seen that the saw no longer leads to the side, and all that remains is to sharpen it.

Sometimes a chip, twig, or branch can get between the bar and the chain. If your chainsaw does not have a chain catcher installed and the bar is long, it can cause serious injury to your ankles if it gets wrapped around it.

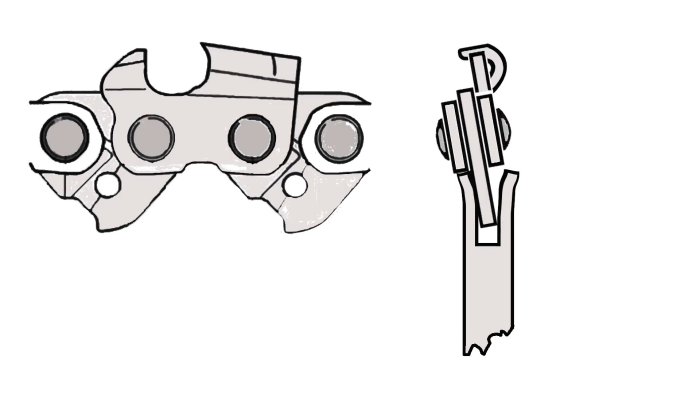

When a chain falls off the tire, the chain catcher takes the brunt of the impact. The sprocket is also damaged. If the chain has jumped off before, then grooves form on the sprocket, interfering with the normal tension of the chain, because when it gets into the groove, the chain sags, and when it jumps out of it, it is greatly stretched. Such a sprocket needs to be changed urgently, otherwise the chain may break, the bearings may crumble, the sprocket welded to the clutch disc may fail and fall off.

And one last thing. Even a new chain can break due to incorrectly installed connecting bars at the riveting site. You need to check the correctness and quality of the riveting in the store when purchasing a chain.